Understanding the gear system basics is essential for anyone interested in mechanics, engineering, or automotive design.

What Is a Gear System?

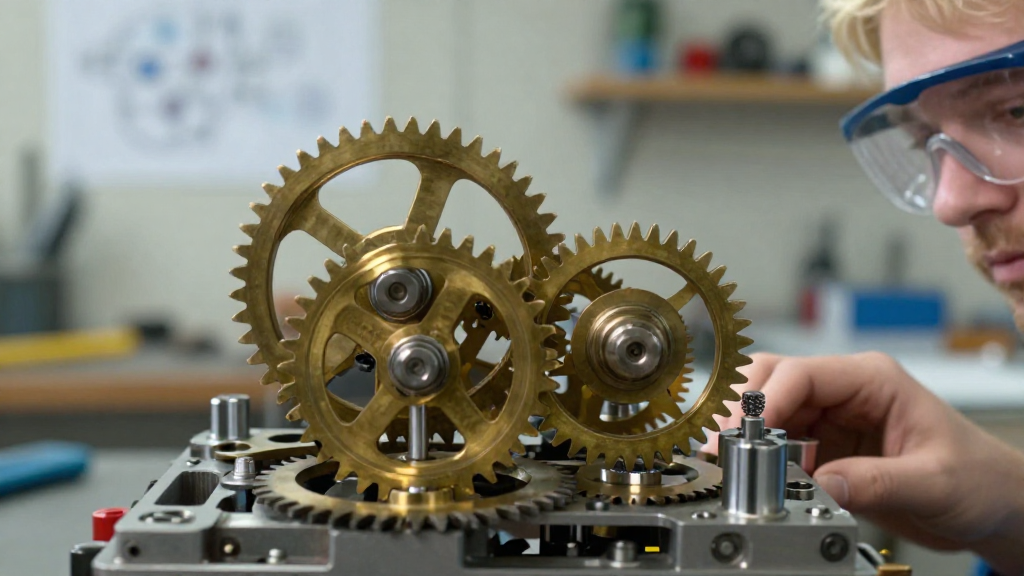

A gear system is a mechanical assembly that utilizes gears to transfer motion and torque between different parts of a machine.

These systems are widely used in various applications, from simple tools to complex machinery.

Gears come in various types, sizes, and arrangements, but they all share one common goal: to change speed, direction, and torque of an output shaft.

Why Are Gear Systems Important?

Gear systems play a crucial role in many industries, including automotive, aerospace, and industrial machinery.

They are essential for:

- Increasing torque: Gears can manipulate force, allowing machines to perform heavy-duty tasks.

- Changing direction: A gear system can redirect movement, making it more versatile.

- Controlling speed: Different gear combinations allow for adjustments in speed, catering to specific performance needs.

What Are the Main Components of a Gear System?

To grasp the gear system basics, it’s essential to understand its primary components, including:

- Gears: The toothed wheels that mesh together to transmit motion.

- Shafts: The rods that connect the gears and support their rotation.

- Bearings: These reduce friction and support the rotation of the shafts.

- Housings: The outer casing that protects and contains the internal components.

Types of Gears in Gear Systems

Several types of gears can be found in gear systems, each serving a specific function.

Here are the most common:

-

Spur Gears:

– Simple and commonly used.

– Feature straight teeth and operate in parallel alignment. -

Bevel Gears:

– Used to change the axis of rotation.

– Have conical shapes, allowing for 90-degree transmissions. -

Worm Gears:

– Provide a high torque ratio.

– Consist of a worm that meshes with a worm wheel. -

Planetary Gears:

– Offer high efficiency and compact design.

– Consist of a central “sun” gear, surrounding planet gears, and an outer “ring” gear. -

Rack and Pinion:

– Converts rotational motion into linear motion.

– Involves a gear (pinion) engaging a flat, toothed bar (rack).

Understanding these gear types is crucial to mastering gear system basics as they determine how the system operates.

How Do Gears Work Together?

Gears must mesh perfectly to ensure smooth operation within a gear system.

Here are some fundamental principles:

- Gear Ratio: This is the ratio of the number of teeth on two gears. It influences the speed and torque output.

-

For example, if Gear A has 10 teeth and Gear B has 20 teeth, Gear B will rotate at half the speed of Gear A, but with twice the torque.

-

Meshing: When gears mesh, one gear turns the next. The motion transferred from one gear to another can either increase or decrease speed and torque, depending on the gear teeth configuration.

How Can Gear Systems Be Configured?

The configuration of a gear system can significantly impact its performance.

Here are a few common configurations:

- Simple Gear Train: Connects two or more gears directly.

- Compound Gear Train: Combines multiple gears on the same shaft for increased speed or torque alterations.

- Reverted Gear Train: Features an intermediate shaft that allows for changes in direction while maintaining gear ratio ratios.

- Differential Gears: Used primarily in vehicles, they allow each wheel to turn at different speeds—vital during turns.

Learning about these configurations is integral to understanding gear system basics.

What Are the Applications of Gear Systems?

Gear systems have a wide variety of applications across different fields, and their versatility makes them invaluable.

Some common applications include:

- Automotive Industry: Used in transmissions and differentials for vehicles.

- Manufacturing Machinery: Employed in conveyor systems and robotic arms.

- Aerospace Engineering: Utilized in aircraft control systems and landing gear mechanisms.

- Consumer Products: Integrated into household items like clocks, toys, and kitchen appliances.

What Are the Advantages of Using Gear Systems?

There are numerous advantages to using a gear system in machinery and other applications.

These advantages include:

- Efficiency: Gears minimize energy loss, making machinery more efficient.

- Reliability: With proper design, gears can reliably transmit power without slipping.

- Flexibility: Different gear combinations can provide precise control over speed and torque according to the application requirements.

What Are the Disadvantages of Gear Systems?

Despite their advantages, there are some drawbacks associated with gear systems.

These include:

- Wear and Tear: As with any mechanical component, gears can wear out over time, necessitating maintenance or replacement.

- Complexity: Multi-gear systems can become complicated, requiring careful engineering and design to function correctly.

- Cost: High-quality gear systems can be expensive to manufacture and maintain.

Understanding the pros and cons can help in making informed decisions when designing or selecting a gear system.

How Do You Maintain a Gear System?

Maintaining a gear system is crucial for its longevity and performance. Key maintenance practices include:

- Regular Inspection: Check for wear and lubrication levels.

- Lubrication: Use the appropriate lubricant to minimize friction.

- Cleaning: Remove any debris or dirt that may impede operation.

- Alignment: Ensure that gears are correctly aligned to prevent undue wear and tear.

These maintenance tasks are essential in ensuring smooth operation and maximizing the lifespan of gear systems.

Conclusion: What Have You Learned About Gear System Basics?

Mastering the gear system basics provides a solid foundation for understanding mechanical systems.

From their fundamental components and working principles to their various applications, gear systems are integral to countless machines used every day.

Gears allow for the manipulation of speed and torque, serving vital roles across industries.

By familiarizing yourself with these concepts, you can gain a greater appreciation for the intricate mechanisms that power modern technology.

By applying this knowledge and adhering to maintenance practices, one can effectively harness the power of gear systems in various applications.