When considering mechanical power transmission, it’s essential to understand the intricacies of bevel gear vs worm gear.

These two types of gears serve unique purposes and offer distinct advantages and disadvantages in various applications.

What are Bevel Gears?

Bevel gears are designed to transmit power between shafts that are typically at right angles to each other.

They come in various types including straight, miter, spiral, and hypoid gears.

Key Characteristics of Bevel Gears

-

Shape: Bevel gears have conical shapes, allowing them to efficiently transfer motion at an angle.

-

Types:

- Straight Bevel Gears: Feature straight teeth and are best used in applications with lower speed and light loads.

- Spiral Bevel Gears: Have curved teeth that provide smoother engagement, making them suitable for higher-speed applications and heavier loads.

- Miter Gears: A type of bevel gear with a 1:1 ratio, used for reversing rotational direction without changing speed.

- Hypoid Gears: A specific type of spiral bevel gear that allows for non-intersecting shafts and offers smoother operation.

Advantages of Bevel Gears

-

Versatility: They can be used to change the direction of shaft rotation.

-

High Efficiency: Their design can result in less backlash than other gear types.

-

Durability: Properly designed and manufactured bevel gears can withstand higher loads.

-

Compact Design: Suitable for tight spaces due to their ability to direct power at an angle.

Disadvantages of Bevel Gears

-

Cost: Higher-quality bevel gears can be more expensive to manufacture.

-

Complexity: They typically require precise alignment during installation to minimize wear and maximize efficiency.

What are Worm Gears?

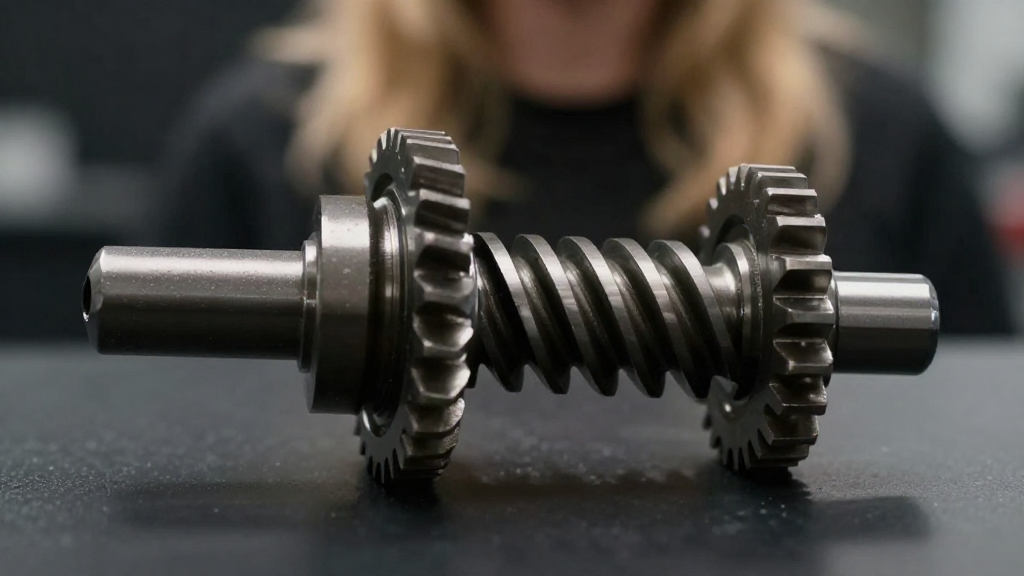

Worm gears consist of a screw-like worm that meshes with a gear resembling a wheel.

This gear arrangement is primarily used for applications requiring significant torque reduction and high-speed reductions.

Key Characteristics of Worm Gears

-

Design: Composed of a worm (the screw) and a worm wheel (the gear), often requiring less space than traditional gear systems.

-

Direction: Generally provides a means for large speed reduction with high torque, making it ideal for lowering rotational speed while increasing torque output.

-

Non-back-driving: Worm gears are known for their ability to prevent back-driving, ensuring that the output does not drive the input.

Advantages of Worm Gears

-

High Reduction Ratios: They can achieve significant speed reductions in a compact system.

-

Self-Locking Ability: The gear design allows for maintenance of position without requiring brakes in many applications.

-

Smooth Operation: Worm gears offer quieter operation due to their unique meshing method.

-

Space-Saving Design: Ideal for applications with limited space due to evolving shapes.

Disadvantages of Worm Gears

-

Efficiency Loss: Due to sliding contact between the worm and gear, they are less efficient compared to bevel gears.

-

Heat Generation: Increased friction can generate heat, necessitating cooling measures in heavy-duty applications.

Bevel Gear vs Worm Gear: Which is Right for Your Application?

When deciding between bevel gear vs worm gear, multiple factors should be considered.

What Factors Should Influence Your Choice?

1. Load Capacity:

– Bevel gears can handle greater loads compared to worm gears.

2. Speed of Operation:

– If high-speed applications are needed, bevel gears might be the better choice.

3. Direction of Power Transmission:

– Both can change the direction of power, but bevel gears can do so more efficiently at 90 degrees or in various configurations.

4. Available Space:

– Worm gears are generally more compact, making them suitable for tight installations.

5. Maintenance:

– Bevel gears typically require more precise alignment for longevity, while worm gears may need less attention due to their simpler installation.

What to Keep in Mind About Bevel Gear vs Worm Gear?

Are There Application Specifics?

-

Automotive: Bevel gears are often used in automotive differentials whereas worm gears find application in elevators due to their self-locking nature.

-

Industrial Machinery: Bevel gears are suitable for lathes, while worm gears are good in conveyor systems.

-

Robotics: Robots may integrate both gear types to manage speed and torque effectively.

Conclusion: Which One Wins?

Ultimately, the choice between bevel gear vs worm gear depends on your specific application needs.

- Speed: Bevel gears excel when high speeds are critical.

- Torque: Worm gears are preferable when high torque is necessary with minimal back-driving.

By understanding bevel gear vs worm gear and their respective advantages and applications, you can make an informed decision tailored to your mechanical engineering needs.

Always analyze your transmission requirements, load characteristics, and operation conditions before making a selection.

For optimal performance, ensure that the selected gear system is engineered and manufactured with high precision and quality standards in mind.