Servo gear systems are essential components in various automation and robotics applications.

They play a crucial role in controlling motion with precision and accuracy.

In this article, we’ll explore what servo gear systems are, how they work, and their applications in various industries.

What Exactly Are Servo Gear Systems?

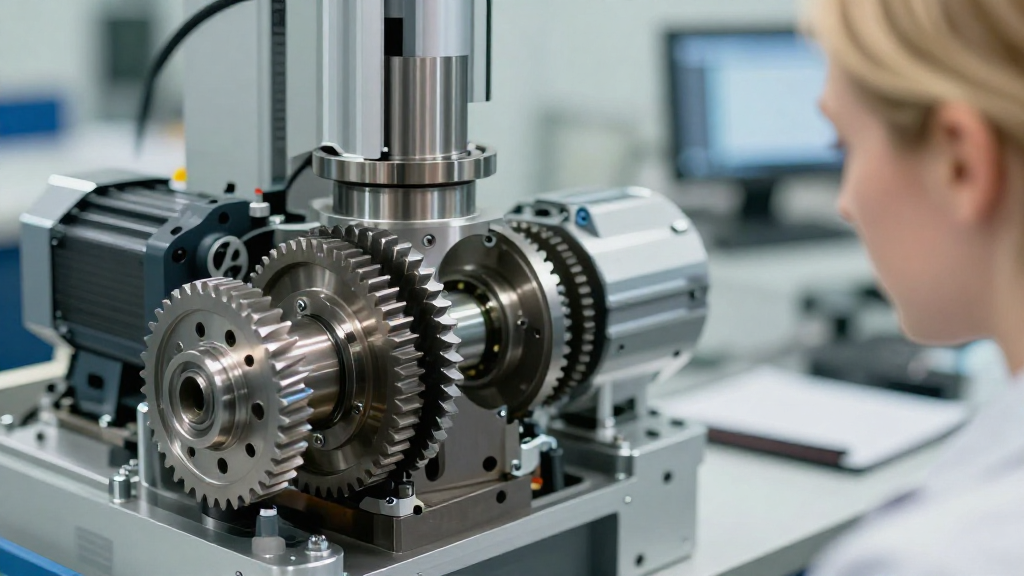

Servo gear systems combine a servo motor with a gearbox to provide controlled rotational motion.

They are designed to enhance the torque output of the motor while also allowing for precise control over speed and position.

How Do Servo Gear Systems Work?

At the heart of five servo gear systems is a servo motor, which converts electrical energy into mechanical motion.

Here’s a simplified explanation of the components involved in these systems:

- Servo Motor: The core component that produces rotational motion.

- Gearbox: A mechanism that reduces speed and increases torque.

Gearboxes often incorporate either planetary or helical gears depending on the application requirements. - Feedback Device: Sensors that provide real-time data on the motor’s position and speed, ensuring precise control.

The Engineering Behind Servo Gear Systems

The operation of servo gear systems is governed by control loops, where the feedback from the sensors is used to adjust the power supply to the motor.

These control loops can be open-loop or closed-loop systems.

- Open-Loop Control: This type doesn’t use feedback for corrections.

- Closed-Loop Control: Utilizes feedback for adjustments, making it far superior in precision and performance.

By integrating these elements, servo gear systems allow for smooth motion, precise positioning, and high torque output.

Why Are Servo Gear Systems Important?

Servo gear systems are vital in applications that require high precision and reliability, such as:

- Industrial Automation: Used in robotic arms and assembly lines.

- Medical Devices: Serves in surgical robots for precise movements.

- Automotive Industry: Used for steering controls and automated driving systems.

- Aerospace: Powering mechanisms in aircraft and spacecraft for reliability and accuracy.

These systems enhance efficiency and improve the functionality of various machines, driving innovations in modern technology.

What Are the Benefits of Using Servo Gear Systems?

Servo gear systems possess several advantages, making them a preferred choice in many applications:

- Precision Control: Enables accurate positioning and speed control.

- High Torque Density: Increases the amount of torque available in a compact size.

- Real-time Feedback: Closed-loop systems provide real-time adjustments for improved performance.

- Energy Efficiency: Consumes less energy while performing high-load tasks compared to traditional motors.

By utilizing servo gear systems, industries can improve operational efficiency and reduce costs.

What Types of Servo Gear Systems Are Available?

Servo gear systems come in various configurations to suit different applications. Here are some common types:

-

Planetary Gear Systems: Known for their compact size and ability to handle high torque loads efficiently.

They are ideal for applications where space is limited. -

Harmonic Drive Gear Systems: Offers a unique design that allows for ultra-precision and high reduction ratios.

Commonly found in robotics and aerospace applications. -

Spur Gear Systems: Simple, straightforward designs that are easy to manufacture and install.

They are often used in straightforward robotics applications. -

Worm Gear Systems: Provides a high gear reduction ratio and can handle high torque applications.

Suited for applications requiring low speed and high torque.

Where Are Servo Gear Systems Used?

Applications for servo gear systems span numerous industries and scenarios, including:

- Robotics: Enabling accurate joint movements for robotic arms and autonomous vehicles.

- CNC Machinery: Offering precise motor control for milling, drilling, and 3D printing.

- Consumer Electronics: In applications like camera gimbals for steady shots and drones for navigation.

- Medical Technology: Serving in devices such as robotic surgical instruments and patient positioning systems.

Servo gear systems are integral for improving performance across these sectors.

How to Choose the Right Servo Gear System?

When selecting the appropriate servo gear system for your application, consider the following factors:

- Load Requirements: Identify the maximum torque and weight that need to be moved.

- Speed and Precision: Assess the required speed and how accurate the positioning needs to be.

- Space Constraints: Verify the physical dimensions and fit within your application.

- Operating Environment: Consider factors like temperature, humidity, and potential exposure to contaminants.

By analyzing these aspects, you can select a servo gear system that meets your application’s needs.

Conclusion: The Future of Servo Gear Systems

In conclusion, servo gear systems are vital components that enhance precision and efficiency in various applications.

From robotics to industrial automation, their utility is undeniable.

As technology continues to evolve, we can expect to see even more innovative applications for these essential systems, contributing to advancements in automation and control.

Whether you’re an engineer designing systems or a business looking to integrate technology, understanding servo gear systems will be key to optimizing performance.

Their ability to provide high torque, precision control, and real-time feedback makes them a cornerstone of modern mechanical design.