When it comes to optimizing machinery for efficiency, gear reducer sizing plays a crucial role in achieving the desired output.

What is Gear Reducer Sizing?

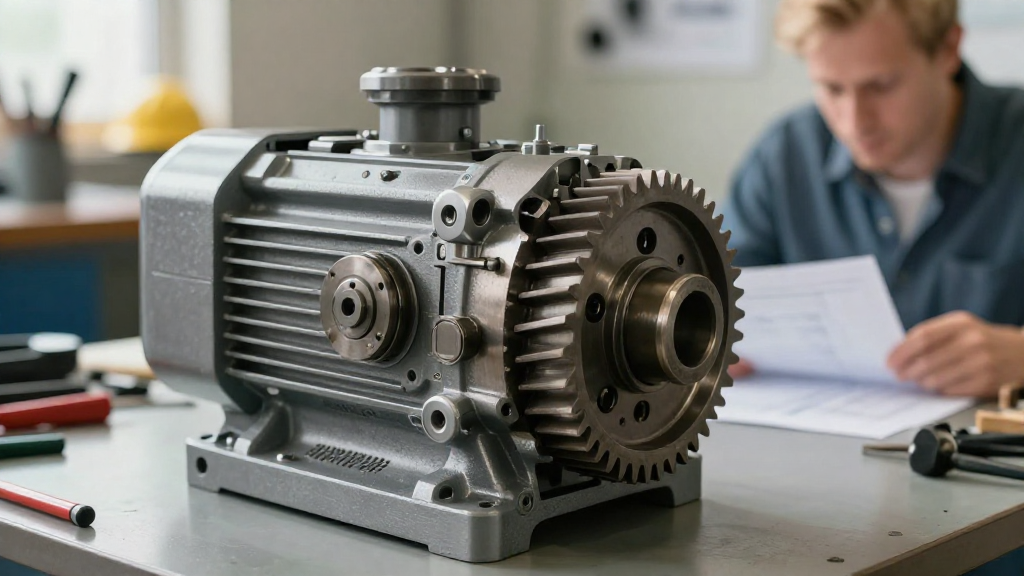

Gear reducer sizing refers to the process of selecting the appropriate gear reduction ratio and sizing a gear reducer to meet specific application requirements. Gear reducers, also known as gearboxes, help reduce speed and increase torque, making them essential components in various machinery and automation processes.

Why is Proper Gear Reducer Sizing Important?

Proper gear reducer sizing is vital because:

- Efficiency: Ensures that the machinery operates at optimal efficiency.

- Longevity: Reduces wear and tear, prolonging the lifespan of the reducer and connected components.

- Performance: Guarantees that the machinery achieves the required output speed and torque.

To achieve these benefits, it is essential to consider several factors during the gear reducer sizing process.

What Factors Should You Consider for Gear Reducer Sizing?

The size and capacity of a gear reducer depend on multiple elements, including:

-

Input Speed:

– Determine the speed of the motor driving the gearbox.

– Understand how this speed will affect the output. -

Required Output Torque:

– Calculate the torque needed at the output shaft.

– Consider the load characteristics of your specific application. -

Load Characteristics:

– Identify whether the load will be constant or fluctuating.

– Assess the peak loads that the reducer must handle. -

Gear Ratio:

– Decide on the required gear ratio based on the application’s speed and torque requirements.

– A higher ratio reduces speed while increasing torque, and vice versa. -

Mounting Type:

– Choose between vertical or horizontal mounting according to space constraints and operating conditions. -

Environment:

– Consider exposure to elements such as heat, humidity, dust, or chemicals.

– Select a reducer with appropriate sealing and cooling features for your environment. -

Service Factor:

– Apply a service factor based on application type and load conditions.

– This can significantly influence the gear reducer sizing process.

How Do You Calculate Gear Reducer Size?

Once you’ve gathered the necessary information, you can proceed with the calculations for gear reducer sizing. Follow these steps:

-

Calculate Required Output Torque:

[

\text{Output Torque (T)} = \frac{\text{Horsepower (HP)} \times 5252}{\text{RPM}}

]

Make sure to convert horsepower to a consistent unit when necessary. -

Determine Gear Ratio:

[

\text{Gear Ratio} = \frac{\text{Input RPM}}{\text{Output RPM}}

]

Choose an appropriate ratio that meets both speed and torque requirements. -

Select Gear Size:

Using the calculated torque and gear ratio, refer to manufacturer charts or guidelines for selecting the proper gear reducer size. -

Account for Efficiency:

Remember that gear reducers are not 100% efficient. Deduct typical efficiency losses (usually between 90-98%) from your torque calculations.

What Types of Gear Reducers are Available?

The market offers various types of gear reducers, each suited for different applications. Here are some common types:

- Helical Gear Reducers: Best for high-speed applications, offering smooth and quiet operation.

- Worm Gear Reducers: Ideal for high torque with a compact design, but they tend to have lower efficiency.

- Bevel Gear Reducers: Suitable for changing the direction of power transmission, often found in right-angle configurations.

- Planetary Gear Reducers: Excellent for high torque applications requiring compact size and high efficiency.

When Should You Consult a Professional?

While this guide outlines the basics of gear reducer sizing, complexities may arise in certain applications. Consider consulting a professional if:

- Your application has unique requirements that cannot be addressed with standard sizing methods.

- The load characteristics involve critical or dynamic operations.

- You require verification of your calculations to ensure safety and performance.

Professional advice can help streamline your choices and potentially save time and money while ensuring the best performance from your gear reducer.

How Can You Validate Your Gear Reducer Selection?

Validating your gear reducer sizing selection is essential for ensuring optimal performance. Here are a few steps to help you confirm your choice:

-

Run Calculations Twice:

– Always double-check your calculations to avoid costly mistakes. -

Prototype Testing:

– If feasible, test your setup on a smaller scale or use simulation software to analyze performance. -

Manufacturer Support:

– Reach out to the gear reducer manufacturer for insights or clarification on your selection. -

Performance Monitoring:

– After installation, monitor for signs of inefficiency or overheating, and make adjustments as necessary.

Conclusion: Is Your Gear Reducer Sized Correctly?

Correct gear reducer sizing is pivotal in ensuring machinery runs efficiently and reliably.

With proper attention to factors such as input speed, torque requirements, load characteristics, gear ratios, and environmental conditions, you can make informed decisions that will enhance the performance and longevity of your system.

By taking the time to carefully assess your application needs and validate your choices, you’re ensuring a smoother operation, a better return on investment, and an extended service life for your machinery.

Proper gear reducer sizing isn’t just about choosing the right equipment; it’s about building a foundation for a successful operational strategy.

Use the guidelines in this article as a reference, and don’t hesitate to seek professional assistance when necessary. The right gear reducer can make all the difference in your equipment’s performance and durability.