A cycloidal drive mechanism is a unique and highly efficient mechanical system that converts rotational motion into oscillatory motion.

This article explores the functionality, applications, and advantages of this intriguing drive mechanism.

What Are the Basic Components of a Cycloidal Drive Mechanism?

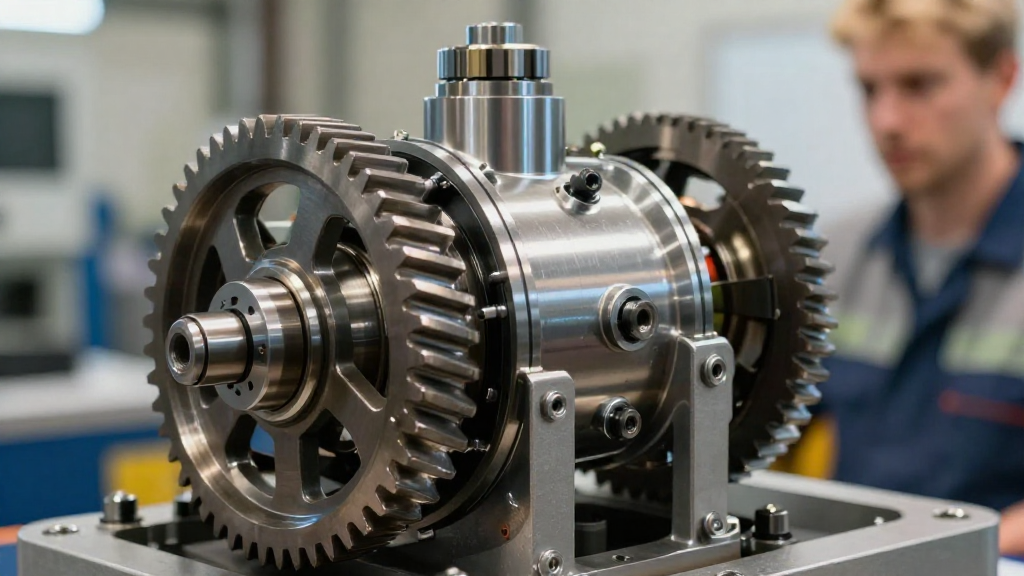

A cycloidal drive mechanism typically consists of several key components:

-

Input Shaft: The shaft that provides the initial rotational motion.

-

Eccentric Disk: This component is affixed to the input shaft and is crucial for converting rotational motion into cycloidal motion.

-

Cycloidal Disc: A specially shaped disc that rolls inside the cycloidal drive, causing the output shaft to rotate.

-

Output Shaft: This shaft receives the motion from the cycloidal disc and transmits it to the next mechanical component.

-

Bearings: These allow smooth motion and support the movement of the components.

-

Casing: The housing that encases all the components, protecting them from external risks.

Each of these components works together to ensure smooth operation and high efficiency, which are essential characteristics of the cycloidal drive mechanism.

How Does a Cycloidal Drive Mechanism Work?

The operation of a cycloidal drive mechanism involves a series of motions:

-

The input shaft rotates, causing the eccentric disk to also rotate.

-

As the eccentric disk turns, it drives the cycloidal disc in a circular path.

-

The uniquely shaped cycloidal disc then engages with the output shaft in such a way that it converts the circular motion into a more efficient oscillating motion.

-

The output shaft rotates at a reduced but more controlled rate, creating smooth and powerful output without significant backlash.

This conversion of motion is one of the primary advantages of the cycloidal drive mechanism.

What Are the Advantages of Using a Cycloidal Drive Mechanism?

The cycloidal drive mechanism offers numerous benefits that make it an attractive option for various applications:

-

High Torque Capacity: Cycloidal drives can handle substantial loads, making them ideal for heavy machinery.

-

Compact Design: The cyclical motion allows for a smaller design, which saves space in applications where size is a constraint.

-

Efficiency: They exhibit low energy losses during operation, resulting in higher efficiency compared to other drive systems.

-

Low Backlash: The unique motion minimizes backlash, which improves accuracy in applications requiring precise positioning.

-

Durability: Cycloidal drives are constructed to withstand demanding environments, making them reliable for long-term use.

-

Thermal Stability: Their design allows them to remain effective even in varying temperature conditions.

These advantages are some of the reasons the cycloidal drive mechanism is increasingly popular in various industries.

Where Are Cycloidal Drive Mechanisms Commonly Used?

The versatility of the cycloidal drive mechanism enables its application in multiple fields, including:

-

Robotics: They are widely used in robotic joints and actuators where precision motion is crucial.

-

Automated Machinery: These mechanisms find extensive use in manufacturing equipment that requires high torque and low backlash.

-

Aerospace: Cycloidal drives contribute to a range of aerospace applications, including landing gear actuation.

-

Medical Devices: They are utilized in surgical robots and other medical machinery that demands accuracy.

-

Conveyors and Material Handling: Their durability and efficiency make them suitable for heavy-duty conveyor systems.

-

Wind Turbines: Cycloidal drive mechanisms help in turning the rotor of wind turbines, optimizing energy capture.

As technology advances, the applications of cycloidal drive mechanisms are expected to evolve and expand, making them even more prevalent in modern machinery.

How do Cycloidal Drives Compare to Other Mechanisms?

When compared to other drive mechanisms, like worm gears or bevel gears, the cycloidal drive mechanism has some distinct advantages:

-

Higher Power Density: Cycloidal mechanisms provide greater torque and power output relative to their size.

-

Better Load Distribution: The design of the cycloidal mechanisms allows for more even distribution of load, reducing wear and tear.

-

Increased Efficiency: Cycloidal drives generally have a higher efficiency rating (often exceeding 90%) compared to traditional gear systems.

-

Mechanical Simplicity: Fewer moving parts compared to complex gear systems lead to easier maintenance and lower failure rates.

-

Backlash Reduction: Cycloidal drives exhibit remarkably low backlash levels, making them more suitable for applications requiring precision.

These comparative features emphasize the practicality of the cycloidal drive mechanism in applications where performance and reliability are critical.

What Are the Challenges in Using Cycloidal Drive Mechanisms?

Despite the many advantages, utilizing cycloidal drive mechanisms can also present certain challenges:

-

Complex Manufacturing: The intricate components and precise tolerances require advanced manufacturing capabilities.

-

Cost Factor: High precision manufacturing can lead to higher initial costs compared to simpler drive systems.

-

Limited Speed Range: Cycloidal drives may not perform optimally at higher speeds, which could limit their use in fast-paced applications.

-

Weight Considerations: While cycloidal drives are compact, their overall weight may still be a consideration for lightweight applications.

Understanding these challenges is essential for users and manufacturers considering the adoption of the cycloidal drive mechanism.

Conclusion: Is the Cycloidal Drive Mechanism Right for Your Application?

In conclusion, the cycloidal drive mechanism stands out as a highly effective solution for converting rotational motion into controlled oscillatory motion.

With a wide range of applications across various industries, its attributes such as compact design, high torque capacity, and low backlash make it a go-to choice for modern machinery.

However, prospective users must assess their specific requirements against the challenges posed by this mechanism.

As technology continues to advance, the cycloidal drive mechanism is likely to remain at the forefront of innovation, driving efficiency in machinery and robotics for years to come.