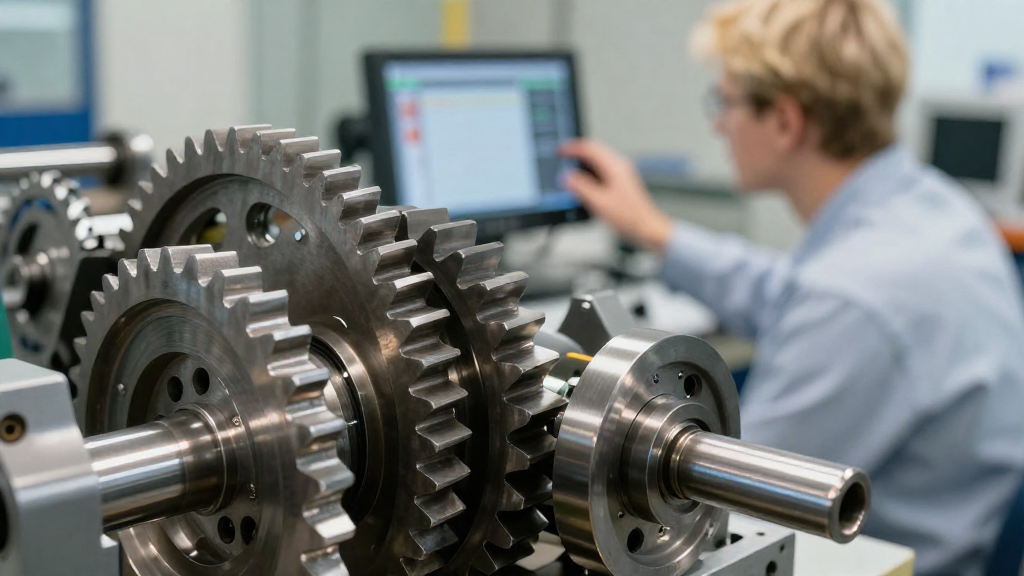

Gear acceleration analysis is a crucial process in mechanical engineering and automotive design.

It involves understanding how gears interact to transfer motion and force, impacting overall system efficiency.

In this article, we will explore various facets of gear acceleration analysis, its methodology, applications, and its significance in modern machinery.

What is Gear Acceleration Analysis?

Gear acceleration analysis assesses the performance of gears in motion.

This process examines how quickly gears can accelerate under different loads, ensuring optimal power transmission and minimizing mechanical failure.

Why is Gear Acceleration Important?

Understanding gear acceleration is essential for several reasons:

- Efficiency: Optimal gear performance improves the overall efficiency of machines.

- Durability: Analysing gear acceleration can predict potential failures and prolong machinery life.

- Performance: Enhancing gear systems leads to better speed and torque output.

How is Gear Acceleration Analyzed?

Gear acceleration analysis encompasses several methodologies:

- Mathematical Modeling: Utilizing equations of motion and torque to predict gear behavior.

- Simulation Software: Leveraging CAD and simulation tools to visualize gear dynamics.

- Real-World Testing: Conducting experiments to measure gear performance under various conditions.

These approaches help engineers develop comprehensive insights into gear acceleration dynamics.

What Factors Affect Gear Acceleration?

Several factors influence gear acceleration, including:

- Gear Design: Tooth profile, material, and size play vital roles in performance.

- Load Conditions: Varying operational loads can alter acceleration rates drastically.

- Lubrication: Proper lubrication reduces friction, optimizing acceleration.

- Speed: Higher initial speeds can affect how quickly the gear accelerates.

Understanding these factors enhances gear acceleration analysis and enables engineers to make informed design decisions.

What Tools are Used in Gear Acceleration Analysis?

The tools employed for gear acceleration analysis vary but often include:

- Finite Element Analysis (FEA) Software: Used to assess stress and performance in gear systems.

- Mechanical Simulation Tools: Allow for dynamic simulation of gear interactions.

- Data Acquisition Systems: Used to gather performance data during testing.

By utilizing these tools, engineers can visualize gear interactions and identify weaknesses in design.

How Does Gear Acceleration Impact Different Industries?

Gear acceleration analysis plays a significant role across various industries:

1. Automotive

In the automotive sector, gear acceleration analysis is vital for:

- Transmission Systems: Ensuring efficient power transfer from the engine to wheels.

- Performance Tuning: Enhancing acceleration and speed of vehicles.

2. Aerospace

In aerospace, gear systems must withstand extreme conditions.

Gear acceleration analysis ensures that:

- Reliability: Gears can perform under high-stress situations without failure.

- Safety: Potential mechanical failures are minimized through effective analysis.

3. Industrial Machinery

For industrial machines, understanding gear acceleration helps in:

- Productivity: Improving machine speed and output.

- Maintenance: Scheduling timely maintenance to prevent breakdowns.

What Are the Challenges in Gear Acceleration Analysis?

While gear acceleration analysis is beneficial, it is not without challenges.

Some common challenges include:

- Complex Interactions: Gears can interact in unpredictable ways due to load changes.

- Precision Requirements: Accurate measurements and calculations are essential for effective analysis.

- Cost: Advanced simulation software and testing equipment can be expensive.

Overcoming these challenges is crucial for effective gear acceleration analysis.

To succeed, engineers must constantly update their knowledge and utilize the latest technologies in their analysis.

How Can Gear Acceleration Analysis be Improved?

Gear acceleration analysis can be improved by integrating new technologies:

- Machine Learning: Utilizing AI to predict gear behavior under various conditions.

- Real-Time Monitoring: Implementing IoT systems to monitor gear performance dynamically.

- Advanced Materials: Developing superior materials that can withstand higher loads and reduce friction.

By focusing on these advancements, the accuracy and effectiveness of gear acceleration analysis will significantly improve.

Conclusion

In summary, gear acceleration analysis is an integral part of modern engineering, impacting various industries from automotive to aerospace.

Understanding the intricacies of gear dynamics can lead to more efficient, durable, and high-performing machines.

As technologies continue to evolve, the methods and tools employed in gear acceleration analysis will also advance, paving the way for innovative designs and solutions.

By keeping abreast of these developments, engineers can ensure their gear systems are optimized for success.

In an era where efficiency and performance are paramount, gear acceleration analysis stands out as a vital area within the mechanical engineering field.

Implementing effective analysis techniques will undoubtedly contribute to the next generation of advancements in gear systems.