A gear speed reducer explained is essential for understanding how machinery operates efficiently through the reduction of speed while increasing torque.

What Is a Gear Speed Reducer?

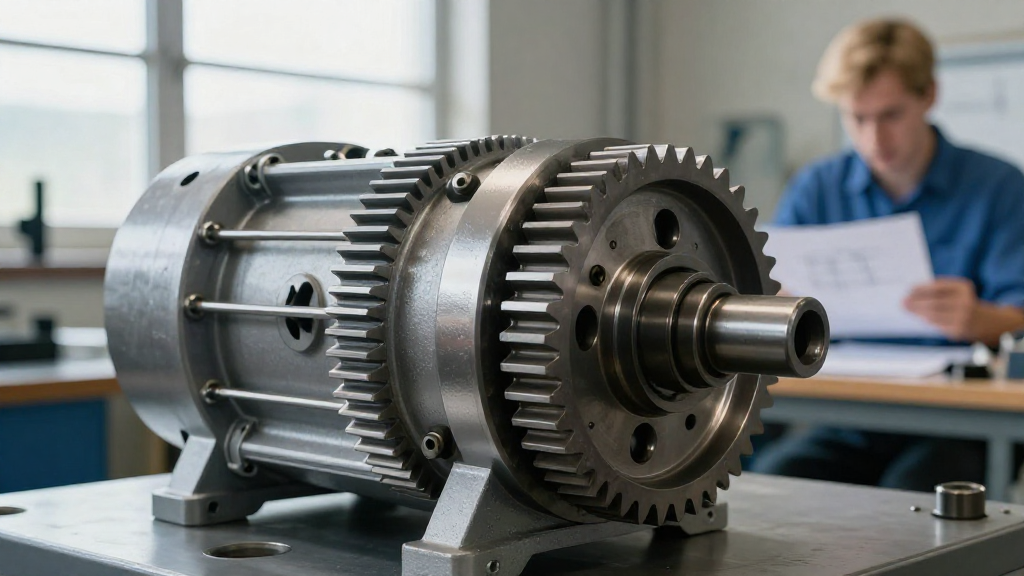

A gear speed reducer, often referred to as a gear reduction unit, is a mechanical device that reduces the speed of an input rotating component while increasing its torque.

This unit is commonly used in various industrial and commercial applications, helping machines achieve the desired balance between speed and power.

How Does a Gear Speed Reducer Work?

The fundamental principle behind a gear speed reducer lies in its gear set, which consists of two or more gears of different sizes.

When the input gear, also known as the driving gear, rotates, it engages the output gear, or the driven gear.

Key Components

- Input Shaft: The shaft connected to the motor that provides power to the system.

- Output Shaft: The shaft from which the reduced speed and increased torque are delivered.

- Gears: Most reducers use a combination of spur gears, bevel gears, or worm gears to achieve the desired speed reduction.

What Are the Benefits of Using a Gear Speed Reducer?

Understanding the advantages of gear speed reducers is crucial for choosing the right machinery for your operations.

Here are some significant benefits:

-

Increased Torque:

– By reducing speed, these units can significantly increase torque output, making them ideal for heavy-duty applications. -

Efficiency:

– Gear speed reducers can operate efficiently with minimal energy loss, contributing to lower operational costs. -

Compact Size:

– They generally have a compact design, making them adaptable to various machinery and space-constrained environments. -

Versatility:

– Suitable for multiple applications, including conveyor systems, robotics, wind turbines, and more. -

Reduced Wear and Tear:

– By distributing loads more evenly, they reduce wear on components, extending the equipment’s lifespan.

Where Is a Gear Speed Reducer Used?

Gear speed reducers are not limited to a specific field.

You will find them in various sectors, including:

- Manufacturing: Used in conveyor belts and automated systems for material handling.

- Automotive: Primarily found in powertrains to optimize engine performance.

- Aerospace: Employed in actuators and propulsion systems for stability and efficiency.

- Construction: Utilized in heavy equipment such as cranes and excavators for improved lifting capabilities.

What Types of Gear Speed Reducers Exist?

1. Worm Gear Reducers

These utilize a worm gear mechanism (a screw-like gear that engages with a traditional gear).

Benefits include:

- High torque output

- Compact design

- Self-locking capabilities to prevent back-driving

2. Spur Gear Reducers

Spur gear reducers employ straight-cut gears.

Advantages include:

- High efficiency

- Ease of manufacturing

- Smooth torque delivery

3. Bevel Gear Reducers

Bevel gear reducers change the drive direction with the help of conical gears.

Key benefits:

- Flexibility in orientation

- Capability of transmitting power at various angles

- High torque availability

4. Planetary Gear Reducers

These reducers contain multiple gears revolving around a central gear (the sun gear).

Advantages include:

- High efficiency

- Compact design

- Excellent torque output

How to Choose the Right Gear Speed Reducer?

Selecting the appropriate gear speed reducer involves several factors:

-

Application Requirements:

– Evaluate the specific load and torque requirements of your application. -

Gear Ratio:

– Understand the desired speed reduction. This will determine the gear ratio you require. -

Mounting Conditions:

– Consider the space available and compatible installation areas for the reducer. -

Efficiency:

– Check the efficiency ratings to ensure minimal energy loss during operation. -

Environmental Conditions:

– Assess the surrounding conditions such as temperature, humidity, and exposure to contaminants.

What Are the Challenges of Using Gear Speed Reducers?

While gear speed reducers offer numerous benefits, they also come with potential challenges:

- Heat Generation: Increased friction can result in heat buildup, reducing efficiency.

- Noise: Some gear types can generate significant operational noise.

- Maintenance Needs: Regular inspections and maintenance are essential to ensure optimal performance and longevity.

- Complexity: Gear reducers can be complex, requiring a higher initial investment and understanding for installation and application.

Why Is Understanding Gear Speed Reducers Important?

Understanding gear speed reducers, described in detail as a gear speed reducer explained, enables engineers and operators to achieve better control over their machinery.

By optimizing these components, businesses can enhance productivity, reduce downtime, and maintain competitive efficiency in their operations.

Conclusion

In summary, a gear speed reducer is a crucial mechanical component that helps manage the balance of speed and torque in machinery.

With various types available, each serving unique applications, understanding their functioning and benefits is vital for selecting the best option for your specific needs.

As we’ve explored, the correct gear speed reducer not only aids efficiency but also plays a significant role in ensuring the longevity and reliability of your equipment.

Whether you’re in manufacturing, automotive, or any other field utilizing machinery, grasping the concept of gear speed reducers is integral to achieving operational excellence.