Gear train power transmission is a fundamental aspect of mechanical engineering that allows machines to function efficiently and effectively. Understanding how gear trains work is crucial for designing systems that require the transfer of motion and torque.

What Is a Gear Train?

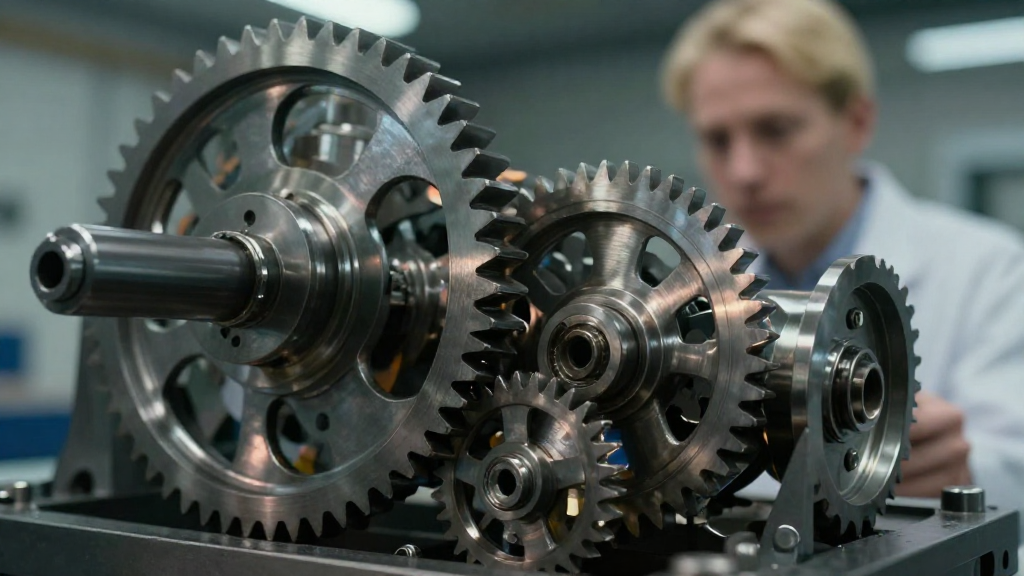

A gear train is a system of gears arranged to transmit motion and power from one component to another.

The gears can vary in size and function, but they usually consist of:

- Driving gear: The gear that serves as the power source.

- Driven gear: The gear that receives the power.

- Intermediate gears: Gears that help in changing the direction or amount of torque.

This interconnected system is what enables effective gear train power transmission.

How Do Gear Trains Connect?

Gear trains connect through interlocking teeth that mesh with each other, allowing for the transfer of rotational force. When the driving gear turns, it moves the driven gear through the intermediate gears. This connection allows for various configurations, including:

- Simple gear trains: Where two gears are present.

- Compound gear trains: Where multiple gears are involved to increase the speed or torque.

These configurations form the backbone of how gear train power transmission operates in practical applications.

Why Are Gear Trains Important for Power Transmission?

What Benefits Do Gear Trains Offer?

Using gear train power transmission offers numerous advantages, including:

-

Torque Multiplication: Larger driven gears result in increased torque.

-

Speed Reduction: Gear trains can reduce speed, providing better control for machinery.

-

Directional Control: Gears can change the direction of motion, making it versatile for various applications.

-

Efficiency: Properly designed gear trains can minimize energy loss.

-

Compact Design: Gear trains enable powerful machines in a smaller footprint.

These benefits are why gear train power transmission is widely used in various machines, from simple hand tools to complex vehicles.

How Are Gears Configured in Gear Trains?

What Are Common Gear Arrangements?

Various configurations of gear trains can be utilized depending on the need for gear ratios and design constraints.

-

Parallel arrangements: Gears are aligned side-by-side, allowing simultaneous movement.

-

Series arrangements: Gears are stacked in a sequence, which can change speed and torque.

-

Planetary arrangements: These include a central gear (sun gear) surrounded by multiple gears (planet gears), enabling compact design and increased torque.

Choosing the right arrangement is crucial in achieving effective gear train power transmission.

How Do Gear Ratios Affect Performance?

What Is the Role of Gear Ratios?

Gear ratios are a critical aspect that influences the performance of gear train power transmission. The gear ratio is determined by the size of the gears involved:

-

A ratio greater than 1 (larger driven gear) provides more torque but reduces speed.

-

A ratio less than 1 (smaller driven gear) gives higher speed but less torque.

Choosing the correct gear ratio ensures that the desired balance between speed and torque is achieved for specific applications.

What Materials Are Used for Gears?

How Do Material Choices Influence Performance?

The materials used in gear construction significantly affect both durability and efficiency.

Common materials include:

-

Steel: Offers high strength and wear resistance, commonly used in industrial applications.

-

Aluminum: Lightweight and resistant to corrosion, suitable for applications where weight is critical.

-

Plastic: Generally used in less demanding applications due to its lower strength but excellent for noise reduction.

-

Composites: Combining materials can yield high strength-to-weight ratios, ideal for advanced engineering applications.

By selecting the appropriate material, engineers can enhance the effectiveness of gear train power transmission.

How Do Lubricants Affect Gear Train Performance?

Why Is Lubrication Essential for Gear Trains?

Lubrication plays a vital role in the longevity and efficiency of gear trains. Proper lubrication reduces friction, which can lead to:

-

Reduced wear: Minimizes damage over time.

-

Heat dissipation: Keeps the gears from overheating, ensuring smoother operation.

-

Noise reduction: Aids in providing a quieter operating environment.

Choosing the right lubricant is essential for maintaining effective gear train power transmission.

How Do You Design an Efficient Gear Train?

What Are Key Design Considerations?

Designing a gear train requires careful consideration of several factors:

-

Load: Understand the load the gear train will bear.

-

Speed requirements: Determine the necessary angular velocities.

-

Space limitations: Design the layout to fit the available space.

-

Cost: Balance performance and budget constraints.

-

Assembly: Ensure that the parts can be easily manufactured and assembled.

By taking these factors into account, engineers can create gear trains that maximize efficiency in power transmission.

How Is Gear Train Power Transmission Used in Industries?

In What Applications Are Gear Trains Common?

Gear train power transmission is found in various sectors, including:

-

Automotive: For transmissions and differential gears.

-

Manufacturing: In conveyor systems or robotic arms for precise control.

-

Aerospace: In mechanisms that require high reliability under variable loads.

-

Robotics: For movement and manipulation, allowing for precise actions.

The versatility of gear train power transmission means it plays a critical role in modern technology.

Conclusion

Understanding how gear trains transmit power is essential for various applications across multiple industries.

From simple devices to intricate machinery, gear train power transmission continues to be a cornerstone of mechanical systems.

By focusing on aspects like material selection, gear ratios, and design considerations, engineers can optimize these systems for better performance, ensuring their ongoing relevance and efficiency in ever-evolving technology.

By appreciating these fundamentals, one can truly grasp the vital role that gear train power transmission plays in modern engineering and manufacturing.