Understanding the internal gear function is essential for those involved in mechanical engineering and design.

Internal gears play a critical role in various machinery and applications, enhancing efficiency and performance.

In this article, we will explore the internal gear function, its components, key applications, and advantages, ensuring a comprehensive understanding of this vital mechanical element.

What Are Internal Gears?

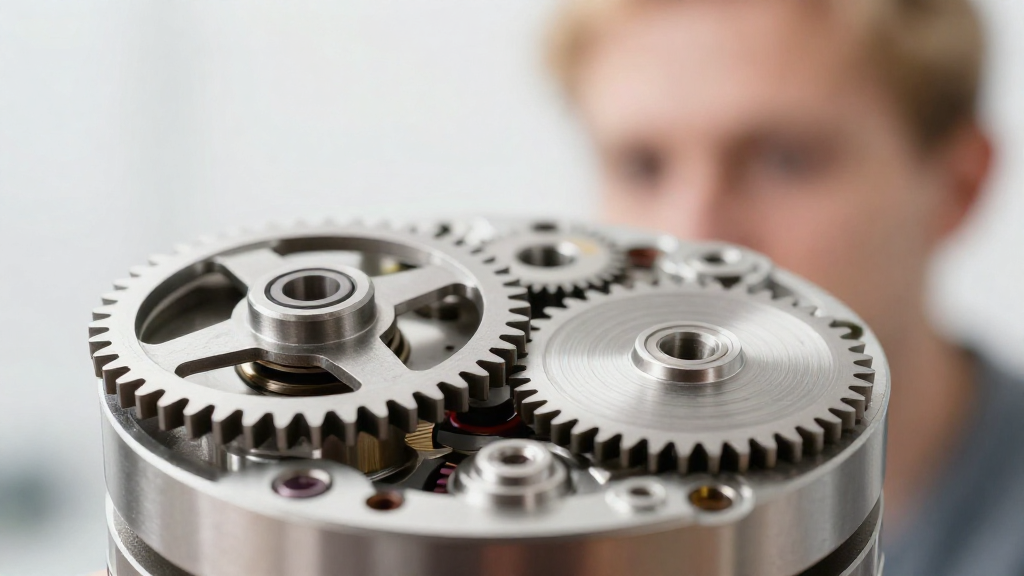

Internal gears are a type of gear with teeth that are cut on the inside surface of a cylindrical wheel.

This means that the gear’s teeth face towards the center of the gear, in contrast to external gears, which have teeth that face outward.

The primary components of an internal gear include:

- Outer Ring: The part of the gear where the teeth are located.

- Pitch Circle: The imaginary circle that defines the size of the gear teeth.

- Center Axis: The central line around which the gear rotates.

These elements combine to facilitate the gear’s function in various mechanical applications.

What is the Internal Gear Function?

The internal gear function is fundamentally about transferring motion and power within machinery.

Here are the essential roles that internal gears play:

-

Torque Increase:

Internal gears can multiply the torque applied to the system, enabling machinery to perform heavy-duty tasks with less effort. -

Compact Design:

They often allow for a more compact arrangement compared to external gears, as the gears can mesh within the same circumference, minimizing space requirements. -

High Load Capacity:

Internal gears can handle greater loads due to the interlocking design, which distributes forces along a larger surface area. -

Noise Reduction:

The enclosed design of internal gears can help reduce noise during operation, making them ideal for applications where noise reduction is crucial. -

Direction Change:

They can effectively change the direction of motion, providing versatility in design.

How Are Internal Gears Used in Machinery?

The internal gear function is utilized in numerous mechanical devices:

1. What Are the Applications of Internal Gears?

Internal gears are found in various applications, such as:

-

Differential Gears in Automobiles:

Internal gears help distribute engine power to the wheels, allowing for smooth turns. -

Worm Drives:

Used in lifting applications, the internal gear function allows for significant torque multiplication with minimal effort. -

Robotic Mechanisms:

They enable precise movements and high load handling, essential for robotic arms and joints. -

Bicycle Gear Systems:

Used in hub gears, internal gears contribute to a more efficient pedaling system.

These applications underline the importance of understanding the internal gear function in mechanical engineering and design.

2. What Are the Advantages of Internal Gears?

The internal gear function comes with several advantages:

-

Efficiency:

Internal gears typically exhibit high efficiency due to their ability to transmit power smoothly. -

Durable Design:

Their robust construction makes them resilient under high loads and adverse conditions. -

Simplified Assembly:

Their compact nature allows for easier integration into various machinery, simplifying assembly processes. -

Reduced Wear:

Distributing the load across multiple teeth reduces wear, leading to a longer lifespan compared to some external gear configurations.

3. How Do Internal Gears Compare to External Gears?

To appreciate the internal gear function, it’s vital to compare it with external gears:

-

Space Requirements:

Internal gears require less space than external gears, as they can fit within the gear rim rather than extend outward. -

Contact Surface:

Internal gears often provide a larger contact surface area, enabling them to handle greater loads and distribute forces more efficiently. -

Backlash:

Internal gears typically exhibit less backlash, which is the play between teeth that can affect the precision of gear movement. -

Cost:

While internal gears may be more complex to manufacture, their efficiency and durability can lead to cost savings in the long run.

4. How Do You Maintain Internal Gears?

To ensure the internal gear function remains optimal, proper maintenance is essential. Here’s how:

-

Regular Lubrication:

Use appropriate lubricants to minimize friction and wear. -

Inspection:

Frequently inspect for signs of wear or damage, including tooth wear and excessive play. -

Alignment Checks:

Ensure proper alignment within the assembly to prevent premature wear and enhance performance. -

Contamination Control:

Keep internal components free from dust and debris, which can interfere with operation.

Conclusion: Why is Understanding Internal Gear Function Important?

Knowing the internal gear function is vital for engineers, designers, and manufacturers.

It contributes to:

-

Design Innovation: Understanding how internal gears function can lead to innovative machinery designs that maximize efficiency and space.

-

Operational Efficiency: It allows businesses to choose the right gear systems, ensuring smoother operations and reduced costs.

-

Sustainability: Efficient machinery often leads to less energy consumption, contributing to more sustainable practices.

In conclusion, the internal gear function is an essential element in machinery design and operation, and its advantages make it a critical component in modern mechanical systems. Understanding this function enables better mechanical design, efficient operations, and longer-lasting equipment.

Whether you are designing a new machine or optimizing existing systems, recognizing the role of internal gears will help you achieve greater performance and efficiency.