Understanding how gearboxes are built is essential for engineers, manufacturers, and enthusiasts alike.

Gearboxes are crucial components in machinery and vehicles, serving to transfer energy and control speed and torque.

In this article, we will explore the various stages of gearbox construction, the materials used, and the technology involved in assembly.

What Are Gearboxes and Their Functions?

Gearboxes, also known as gear reducers or gear trains, are mechanical devices that adjust the output speed and torque of a power source.

They consist of various gears, shafts, and enclosures.

Gearboxes are largely used in automotive applications, industrial machinery, and consumer electronics.

Key functions of gearboxes include:

- Torque Amplification: Gearboxes increase torque output, allowing heavy machinery to function efficiently.

- Speed Reduction: They help in reducing the rotational speed, crucial for applications requiring controlled pacing.

- Direction Change: Gearboxes can also alter the direction of the output shaft, essential for specific mechanical arrangements.

How Are Gearboxes Built?

The process of how gearboxes are built involves several carefully orchestrated steps.

Let’s break down these stages for better understanding:

What Are the Key Materials Used in Gearbox Construction?

The durability and performance of a gearbox heavily depend on the materials used.

Common materials include:

- Steel: Known for its strength, steel is commonly used for gears and shafts.

- Aluminum: Lightweight and resistant to corrosion, aluminum is often used in housing components.

- Plastic Composites: In low-torque applications, plastic materials can be used to reduce weight and cost.

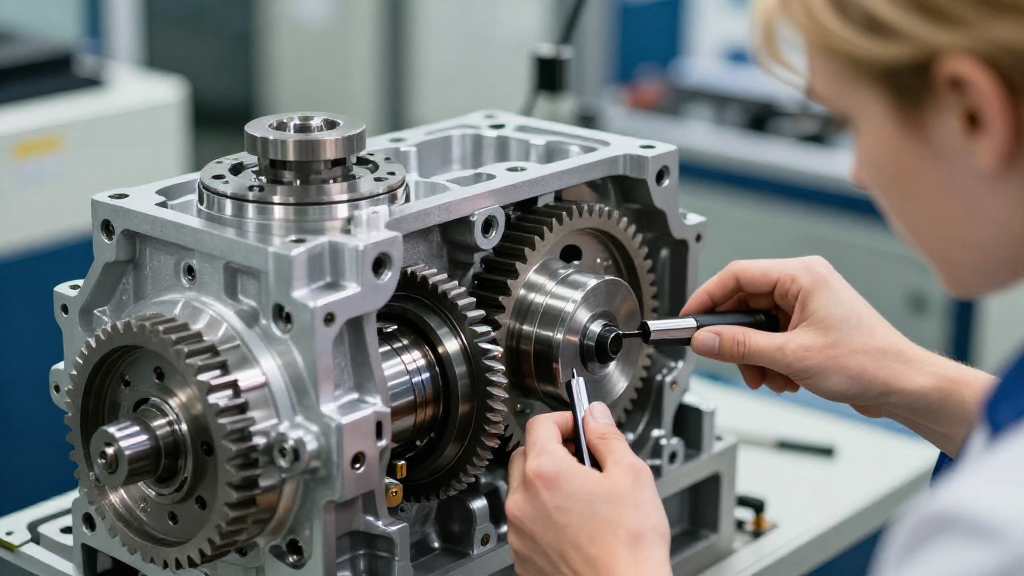

What Are the Essential Components in Gearboxes?

To comprehend how gearboxes are built, it’s essential to identify the main components involved.

A typical gearbox consists of:

- Gears: The primary components that transmit power. Different gear types (spur, helical, bevel) can be employed depending on the application’s needs.

- Shafts: These rods connect gears and transfer torque between them. They must exhibit high tensile strength.

- Bearings: These support the rotating shafts, minimizing friction and wear.

- Housing: The outer shell that encapsulates all the components, providing protection against external elements.

How Are Gear Components Manufactured?

Each part is manufactured using different techniques based on material, design, and application.

Here’s how components are typically made:

-

Machining: Gears and shafts are often machined from solid blocks of metal using processes like milling, turning, or grinding.

-

Casting: For complex shapes or larger parts, casting techniques like sand casting or die casting are used.

-

Forging: This involves shaping materials under high pressure, leading to stronger components due to alignment of the material’s grain structure.

-

Injection Molding: For plastic parts, the injection molding process is commonly employed, whereby molten plastic is injected into molds and allowed to cool.

What Is the Assembly Process of Gearboxes?

Once all components are manufactured, the next stage of how gearboxes are built is assembly.

This process typically involves:

-

Preparation: Inspecting and cleaning parts to ensure they are free of debris and defects.

-

Gear Installation: Gears are placed onto their respective shafts in a manner that facilitates the intended motion.

-

Shaft Installation: With the gears secured, the shafts are aligned and mounted within the housing.

-

Bearing Placement: Bearings are installed to support the shafts, ensuring fluid movement without excessive friction.

-

Housing Assembly: Finally, the outer housing is assembled, sealing all components tightly and safely.

-

Lubrication: Oil or grease is applied to moving parts to minimize wear and optimize performance.

How Are Gearbox Quality and Performance Ensured?

Ensuring top-notch quality is crucial in how gearboxes are built.

Manufacturers implement various testing and inspection protocols throughout the assembly process.

Common quality checks include:

- Visual Inspection: A thorough inspection for any visible defects, ensuring aesthetic and functional quality.

- Dimensional Inspection: Tools, such as calipers and gauges, are used to verify the dimensions of critical components.

- Functional Testing: Gearboxes are subjected to performance testing under simulated operating conditions to assess their functionality and durability.

- Noise and Vibration Analysis: Monitoring for abnormal sounds and vibrations, indicating potential design or assembly issues.

What Technologies Are Used in Gearbox Manufacturing?

Modern gearbox manufacturing has embraced various technologies to enhance efficiency and improve precision.

Some notable advancements include:

-

Computer Numerical Control (CNC) Machines: These provide higher accuracy in machining components, reducing waste and increasing productivity.

-

Automation and Robotics: In assembly lines, robots are often employed for tasks that require precision or involve repetitive work.

-

Advanced Materials: The use of high-strength alloys and composite materials contributes to lighter and more durable gearboxes.

-

Simulation Software: Engineers can simulate gearbox dynamics during the design phase, allowing for better optimization before the physical build.

Why Is Understanding Gearbox Construction Important?

Understanding how gearboxes are built is essential not just for manufacturers but also for end-users.

Benefits of this knowledge include:

- Informed Purchasing: Consumers can make better choices about products based on the design and manufacturing quality of gearboxes.

- Maintenance Awareness: Knowing how gearboxes are constructed helps in understanding their maintenance needs and how to troubleshoot issues effectively.

- Innovation: Engineers and designers can draw on knowledge of construction to innovate and improve existing designs for enhanced efficiency and performance.

Conclusion

In summary, how gearboxes are built is a multi-faceted process requiring careful attention to detail, quality control, and the use of advanced materials and technology.

By understanding the materials, components, manufacturing techniques, and assembly processes involved, one can appreciate the complexity and significance of gearboxes in various applications.

Armed with this knowledge, stakeholders can make informed decisions, ensuring that gearboxes perform optimally in their intended roles.

Whether in a factory, a vehicle, or consumer electronics, the importance of a well-built gearbox cannot be overstated.