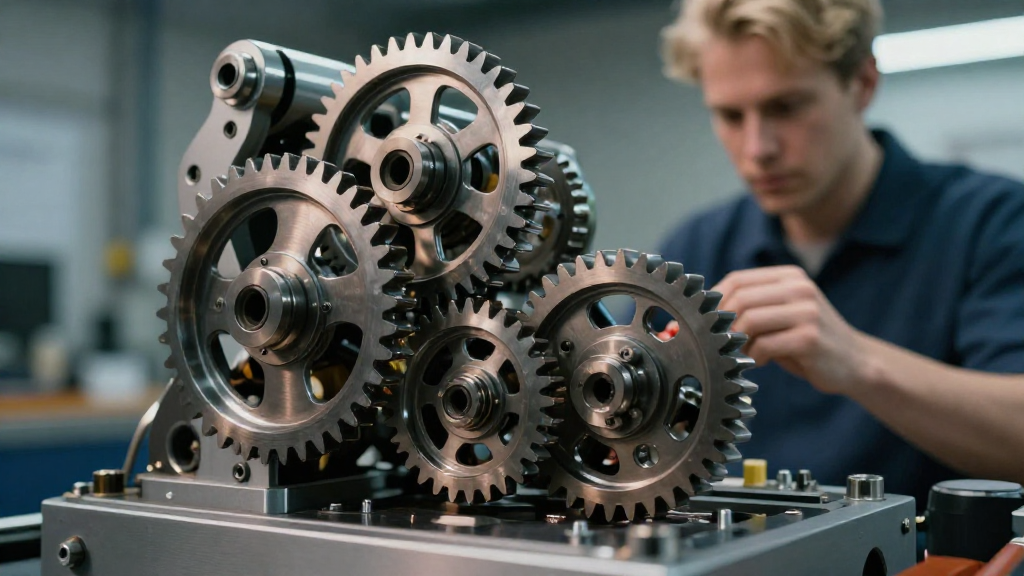

Gear systems in robotics are critical components that help machines achieve precise motion and control. Understanding how these systems work is essential for anyone interested in designing or working with robotic applications.

What Are Gear Systems in Robotics?

Gear systems in robotics refer to the mechanical assemblies that use gears to transmit power and control motion. They play a pivotal role in converting the input motion of motors into usable output motion.

How Do Gear Systems in Robotics Work?

Gear systems in robotics function on the principles of mechanics and physics. At the core, gear systems consist of two or more gears that mesh together to transmit motion.

When one gear, called the driving gear, turns, it causes the adjacent driven gear to turn as well.

This interaction allows for:

-

Speed Variation: By altering the size of the gears, engineers can manipulate the speed of the robot’s movement.

-

Torque Amplification: Larger gears can amplify the torque provided by a motor, allowing for stronger movements.

-

Direction Control: Gear arrangements can change the direction of movement, crucial for navigating complex tasks.

What Are the Types of Gear Systems in Robotics?

There are several types of gear systems in robotics, each designed for specific functionalities:

-

Spur Gears: These are the most common type of gear used in robotics, featuring straight teeth aligned parallel to the axis. They provide high efficiency and are ideal for simple applications.

-

Helical Gears: With teeth that are cut at an angle, helical gears offer smoother and quieter operation than spur gears. They are suitable for high-speed applications.

-

Bevel Gears: These gears are used to change the axis of rotation. Bevel gears are commonly utilized when a right-angle change of direction is required.

-

Worm Gears: A worm gear consists of a screw (worm) and a gear wheel (worm wheel). This system provides high torque and is ideal for applications requiring significant gear reduction.

-

Planetary Gears: This system comprises a central gear (sun gear) surrounded by other gears (planet gears). Planetary gear systems compactly fit into machines while providing high torque and multiple output speeds.

Why Are Gear Systems Essential in Robotics?

Gear systems in robotics are fundamental for several reasons:

-

Precision Control: They enable robotic arms and legs to move with incredible accuracy, critical for tasks such as assembly and surgery.

-

Load Handling: Gear systems allow robots to carry heavy weights by distributing the load evenly across the gears, ensuring stability during operations.

-

Safety: Many gear systems include fail-safes that prevent mechanical overload, improving the reliability of robotic systems.

How Are Gear Systems in Robotics Designed?

The design process for gear systems in robotics involves several steps:

-

Determining Specifications: Defining the necessary torque, speed, and direction requirements based on the robotic application.

-

Calculating Gear Ratios: The gear ratio represents the relationship between the input and output shaft speeds. It dictates how much speed is gained or lost and how much torque is provided.

-

Choosing Gear Types: Based on the project needs, engineers select the appropriate types of gears (spur, helical, bevel, worm, or planetary).

-

Material Selection: Gear materials must be chosen for durability, friction reduction, and weight. Common materials include steel, plastic, and composites.

-

Prototyping and Testing: Engineers create prototypes to test the efficiency and effectiveness of the gear system in real-world applications.

What Are the Challenges in Gear Systems in Robotics?

While gear systems in robotics offer many advantages, they also come with challenges:

-

Wear and Tear: Gears can degrade over time due to constant friction and stress, requiring regular maintenance.

-

Noise: Some gear types, like spur gears, can create significant noise. This can be a concern in applications requiring quiet operation.

-

Heat Generation: High levels of friction can cause gears to heat up, damaging the components over time.

How Can Gear Systems in Robotics Be Improved?

Improving gear systems in robotics involves innovation and technology integration:

-

Using Advanced Materials: Incorporating lightweight, high-strength composites can reduce wear and friction, extending the life of the gear system.

-

Implementing Lubrication Systems: Automated lubrication systems can reduce friction and enhance performance, particularly in high-load situations.

-

Incorporating Sensors: Adding sensors can allow for real-time monitoring of gear performance, enabling predictive maintenance and reducing unexpected failures.

Where Are Gear Systems in Robotics Used?

Gear systems in robotics find applications across various industries:

-

Manufacturing: Robotic arms equipped with gear systems are essential in assembly lines for tasks such as welding and painting.

-

Healthcare: Surgical robots with precise gear systems assist surgeons in performing minimally invasive procedures.

-

Aerospace: Gear systems control robotic components in drones and spacecraft, facilitating operation in challenging conditions.

Conclusion

Gear systems in robotics are integral to creating efficient, reliable, and precise machines.

Understanding the various types, functions, and design challenges can help developers enhance the capabilities of robotic systems.

The evolution of gear systems continues to push the boundaries of what is achievable in robotics, paving the way for innovative solutions across industries.

As technology advances, we can expect to see even more efficient and advanced gear systems in robotics, changing the landscape of automation and artificial intelligence for decades to come.

In summary, gear systems in robotics are not only foundational but also dynamic and constantly evolving as we strive for greater efficiency and precision in robotic designs.