Understanding how manual gearboxes work is essential for anyone keen on vehicles or mechanics.

Manual gearboxes, also known as standard or stick-shift transmissions, are fascinating components in many vehicles.

They allow drivers to have direct control over the car’s power and acceleration.

In this article, we will explore how manual gearboxes work, their components, and how they differ from automatic transmissions.

What Are the Main Components of a Manual Gearbox?

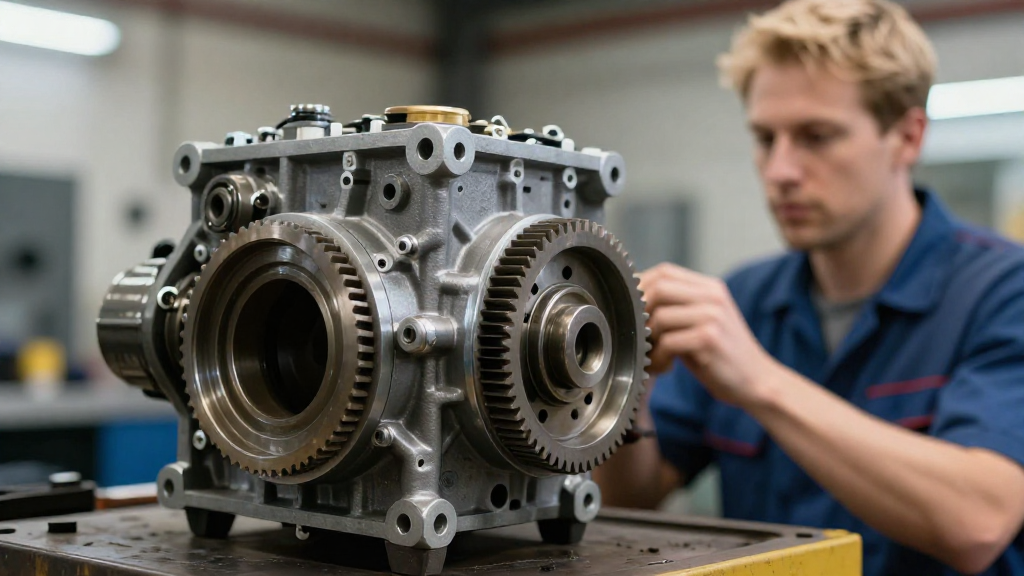

Before diving deep into how manual gearboxes work, it’s essential to familiarize yourself with their key components.

These components work together to manage the vehicle’s speed and torque effectively.

-

Clutch:

– The clutch is perhaps the most crucial component in a manual gearbox.

– It allows the driver to disengage the engine from the wheels when shifting gears. -

Gear Selector:

– The gear selector is the lever that the driver moves to choose different gears.

– It connects to a system of rods and linkages that enable gear changes. -

Gears:

– Manual gearboxes contain an array of gears, typically ranging from three to six forward gears.

– Each gear is designed to transmit different amounts of torque and speed. -

Shafts:

– The input shaft connects to the engine while the output shaft connects to the drive wheels.

– Power transfers through these shafts, causing the wheels to turn. -

Synchronizers:

– These components help to match the speeds of the gears while shifting to enable smooth changes without grinding.

Understanding these components is vital to comprehend how manual gearboxes work effectively.

How Do Manual Gearboxes Work During Gear Changes?

At its core, a manual gearbox operates by manually switching gears to optimize engine efficiency and performance.

Here’s a simple breakdown of how manual gearboxes work during gear changes:

-

Depressing the Clutch Pedal:

– To initiate a gear change, the driver presses down the clutch pedal.

– This action disengages the engine power from the wheels, allowing smooth shifting without mechanical conflict. -

Selecting a Gear:

– Once the clutch is depressed, the driver moves the gear selector to the desired gear.

– Each gear represents a different ratio of engine power and speed. -

Engaging the Gear:

– After selecting the appropriate gear, the driver slowly releases the clutch pedal.

– As the clutch engages, the gear starts to connect with the drive shaft, transferring engine power to the wheels. -

Increased Speed or Torque:

– Depending on the gear selected, the vehicle either accelerates faster or generates more torque for climbing hills or towing. -

Repeat as Necessary:

– This process repeats as the driver shifts through gears while driving.

– Drivers shift up for acceleration and down for deceleration or increased torque.

Now that we have a clearer understanding of how manual gearboxes work during gear shifts, it’s important to look into why many drivers prefer manual transmissions over automatics.

Why Do Drivers Prefer Manual Gearboxes?

While automatic transmissions have gained popularity, many drivers still prefer manual transmissions.

Here are some reasons why:

- Driver Control:

-

Manual gearboxes provide drivers with greater control over the vehicle’s power and acceleration.

-

Performance:

-

Often, vehicles with manual gearboxes can achieve better acceleration and fuel efficiency due to the direct engine connection.

-

Cost:

-

Manual vehicles tend to be less expensive to purchase and maintain compared to automatics.

-

Engagement:

- Many car enthusiasts enjoy the driving experience that a manual gearbox offers, creating a more engaged feel on the road.

By understanding these benefits, one can appreciate how manual gearboxes work and the value they hold for many drivers.

How Do Manual Gearboxes Compare to Automatic Transmissions?

To further comprehend how manual gearboxes work, it’s helpful to contrast them with their automatic counterparts.

Here are some of the significant differences:

-

Operation:

– Manual gearboxes require the driver to manually shift gears, while automatics shift gears automatically based on speed and throttle input. -

Control:

– Manual gearboxes allow for more precise control of engine power.

– Automatic transmissions can sometimes lead to less driver involvement. -

Mechanical Complexity:

– Manual gearboxes are generally simpler and have fewer moving parts, making them easier and cheaper to repair. -

Fuel Efficiency:

– In many cases, manual gearboxes offer better fuel efficiency, especially in older models where automatics were less efficient.

Understanding these distinctions can give a clearer picture of how manual gearboxes work within the broader framework of automotive technology.

What Is the Maintenance for Manual Gearboxes?

Like any vehicle component, manual gearboxes require regular maintenance to ensure long-lasting functionality.

Here are some routine maintenance tips:

- Fluid Checks:

-

Regularly check and change the transmission fluid to ensure smooth operation.

-

Clutch Inspection:

-

Pay attention to clutch wear and replace the clutch disk as necessary to prevent shifting issues.

-

Gear Linkages:

-

Ensure that the gear selector and linkages are properly lubricated and functioning.

-

Drive Shaft Care:

- Inspect and maintain the input and output shafts to prevent power transmission issues.

Following these maintenance tips can extend the life of the manual gearbox and enhance the driving experience.

Conclusion: Understanding How Manual Gearboxes Work

In summary, knowing how manual gearboxes work requires understanding their components, operation, and care.

Manual gearboxes provide a unique driving experience that offers enhanced control, performance, and engagement.

While they might require more effort than automatic transmissions, the rewards include a deeper connection to the vehicle and the road.

With the right knowledge and maintenance, drivers can enjoy the longevity and performance of their manual gearboxes for years to come.

So, whether you’re a seasoned driver or a novice behind the wheel, understanding how manual gearboxes work can enrich your driving experience and appreciation of automotive mechanics.