An epicyclic gear train is a complex system of gears that can achieve high torque and compact design, making it invaluable in various mechanical applications.

How Does an Epicyclic Gear Train Work?

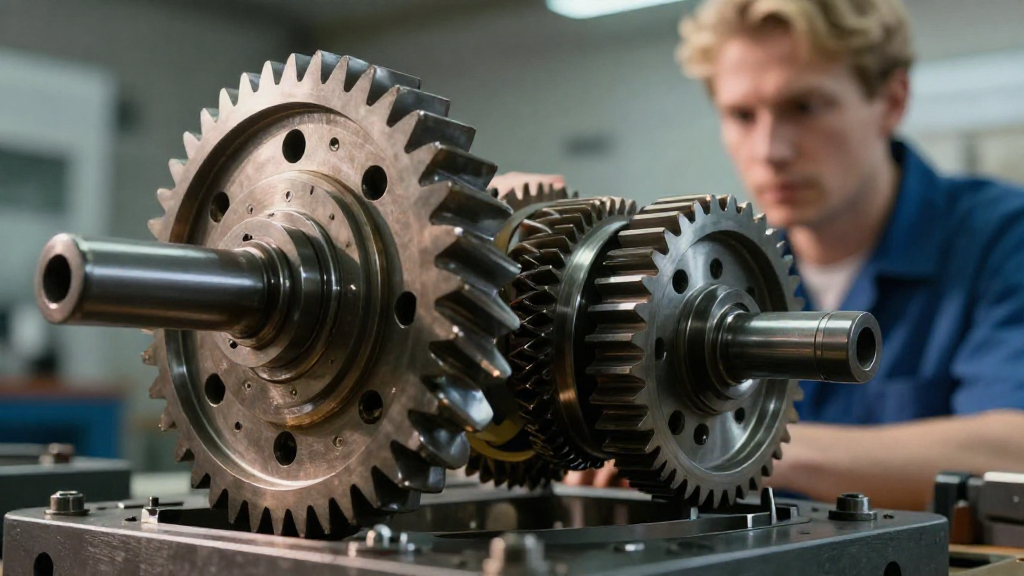

An epicyclic gear train, also known as a planetary gear system, features a unique arrangement of gears consisting of a sun gear, planet gears, and a ring gear. Here’s how these components interact:

- Sun Gear: This is the central gear that drives the entire system.

- Planet Gears: These are smaller gears that rotate around the sun gear. They are typically mounted on a rotating arm called a planet carrier.

- Ring Gear: This gear encircles the planet gears and has teeth on the inner circumference. It is often stationary or can also rotate.

In operation, when the sun gear turns, the planet gears revolve around it while also spinning on their own axes, resulting in a more complex motion that divides power effectively throughout the system.

What Are the Key Features of an Epicyclic Gear Train?

The epicyclic gear train has several unique features:

- Compact Design: The arrangement of gears allows for a more compact assembly that can deliver high torque, which is beneficial in limited spaces.

- High Efficiency: This system reduces friction and maintains a smooth operation, leading to increased efficiency.

- Load Distribution: By distributing the load across multiple planet gears, the system enhances durability and reduces wear.

- Versatile Applications: The epicyclic gear train is appropriate for various applications like automatic transmissions in vehicles, wristwatches, and industrial machinery.

Why Is an Epicyclic Gear Train Popular in Engineering?

The popularity of the epicyclic gear train in engineering can be attributed to several factors:

- Space-Saving: Manufacturers often face space constraints.

- Weight Reduction: A compact design means less weight, critical in aerospace and automotive industries.

- Torque Multiplication: The gear ratios can be optimized for high torque outputs.

- Reduced Parts Count: Fewer components mean lower manufacturing costs and less potential for failure.

Where Is the Epicyclic Gear Train Used?

The epicyclic gear train finds application across various sectors. Here are some notable use cases:

-

Automotive Industry:

– Used in automatic transmissions to facilitate smooth shifting of gears.

– Enable power transfer in hybrid and electric vehicles. -

Aerospace Applications:

– Integrated into engines and landing gear systems due to their lightweight and compact nature. -

Robotics:

– Utilized for precision motion control in robotic arms and joints. -

Industrial Machinery:

– Employed in conveyor systems, cranes, and other heavy machinery for efficient power transmission. -

Wind Turbines:

– Used to convert and optimize rotational movement from turbine blades into usable energy.

What Are the Advantages of Using an Epicyclic Gear Train?

There are numerous advantages of employing an epicyclic gear train in mechanical designs:

- Increased Torque Density: Its design allows for high torque to be generated within a small volume.

- Reduced Backlash: The arrangement of gears minimizes the gap between gear teeth, leading to smoother operations.

- High Gear Ratios: It provides a wide range of gear ratios, enabling versatility in speed and torque output.

- Durability: With multiple planet gears, the stress is distributed, thus enhancing the lifespan of components.

What Are the Disadvantages of an Epicyclic Gear Train?

Despite its advantages, there are some disadvantages to consider with the epicyclic gear train:

- Complex Design: The intricate design can make the system more difficult to manufacture and assemble.

- Cost: Generally, an epicyclic gear train may be more expensive compared to simpler gear systems due to its complexity.

- Maintenance: Repairing or servicing an epicyclic gear train can be more complicated, requiring specialized knowledge and tools.

How to Choose the Right Epicyclic Gear Train for Your Needs?

When selecting an epicyclic gear train for your application, consider the following factors:

-

Torque Requirements:

– Determine the amount of torque the system will need to handle. -

Space Constraints:

– Assess the available space for installation to ensure the epicyclic gear train will fit. -

Efficiency Needs:

– Factor in the required efficiency levels based on your application’s performance metrics. -

Material Choices:

– Select materials based on durability and weight to maximize performance. -

Cost:

– Balance your budget with the technical requirements of your project to find the optimal gear train solution.

Conclusion: Is an Epicyclic Gear Train Right for You?

In conclusion, an epicyclic gear train is a powerful tool in modern mechanical engineering, providing high efficiency, compact design, and versatility.

It is particularly beneficial for applications in challenging environments where space and weight are significant constraints.

If you’re in the market for an efficient and robust gear solution, consider the advantages and varying applications of the epicyclic gear train to determine its suitability for your needs.

As technology continues to advance, the potential for further innovations within the realm of epicyclic gear-based systems appears promising, potentially leading to even more efficient designs in the future.