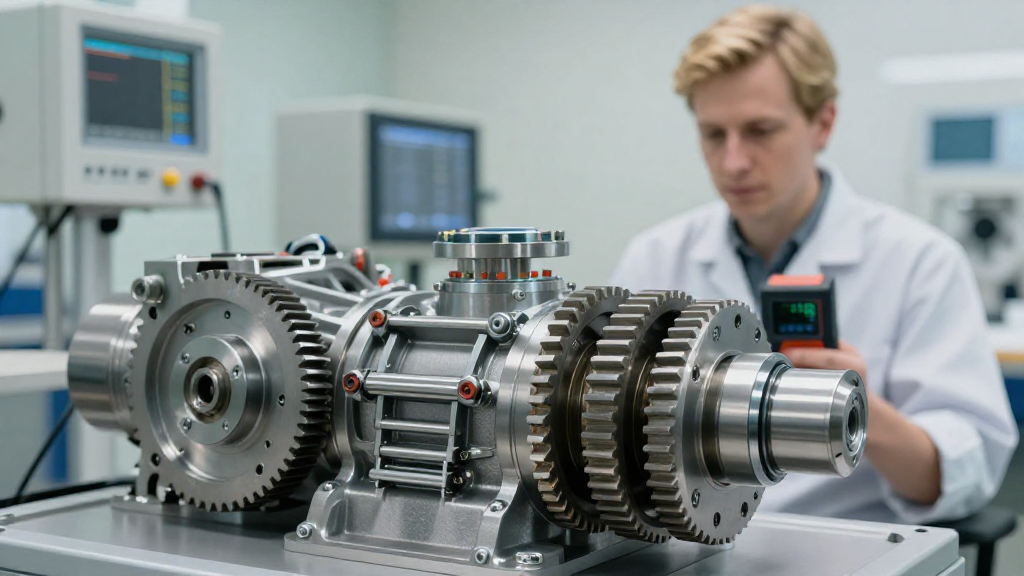

Gearbox vibration analysis is a crucial process for maintaining the efficiency and longevity of industrial machinery.

Understanding how to effectively analyze these vibrations can prevent unplanned downtimes and costly repairs.

In this article, we will explore the various aspects of gearbox vibration analysis, providing you with the knowledge necessary to identify issues and implement corrective actions.

What Is Gearbox Vibration Analysis?

Gearbox vibration analysis refers to the process of monitoring and analyzing the vibration levels produced by a gearbox during operation.

Vibration data provides insights into the health of the gearbox, helping to detect issues such as misalignment, wear, or damaged components.

Key benefits of gearbox vibration analysis include:

- Early fault detection: Identifying problems before they escalate.

- Prolonged equipment life: Reducing wear and tear through timely maintenance.

- Cost savings: Minimizing unexpected downtime and repair costs.

- Improved safety: Reducing the risk of catastrophic failures that could pose hazards to personnel.

Why Is Gearbox Vibration Important to Analyze?

Analyzing gearbox vibrations is essential because they can indicate potential problems that might compromise operational efficiency.

Neglecting these vibrations could lead to severe issues such as:

- Increased operational costs: Unrecognized faults can lead to efficiency losses.

- Equipment failure: Sudden breakdowns may occur without warning.

- Decreased productivity: Production interruptions can lead to lost revenue.

Recognizing these signs early through effective gearbox vibration analysis ensures that you can address faults before they lead to significant complications.

How Does Gearbox Vibration Occur?

Vibration in gearboxes typically arises from various sources. Here are some common causes:

- Misalignment: When components are not properly aligned, excessive vibration is generated.

- Imbalance: Uneven mass distribution can lead to oscillatory forces.

- Wear and tear: Deterioration of gears or bearings increases vibration levels.

- Faulty components: Damage to gears, bearings, or associated parts causes irregular vibration patterns.

- Lubrication issues: Insufficient or contaminated lubricants can lead to increased friction and vibration.

Understanding the root causes of gearbox vibration is critical for effective analysis and remediation.

How to Measure Gearbox Vibration?

To systematically perform gearbox vibration analysis, the following steps and tools are essential:

1. Equipment and Tools

Several tools are commonly used in gearbox vibration analysis:

- Vibration analyzers: These devices measure vibration levels in terms of frequency, acceleration, displacement, and velocity.

- Data acquisition systems: Systems used to collect and display real-time vibration data.

- Portable diagnostic tools: Handheld tools that provide quick measurements and snapshots of gearbox vibrations.

2. Vibration Measurement Techniques

The measurement techniques employed can vary based on applications. Common methods include:

- Time-domain analysis: Captures vibration signals over time to identify characteristics and trends.

- Frequency-domain analysis: Breaks down the vibration signals into their frequency components for detailed fault diagnosis.

- Orbit plots: Visual tools that help understand the motion traces of rotating equipment.

3. Sensor Placement and Data Collection

Correct sensor placement is vital for accurate data. Follow these guidelines:

- Mount sensors directly on the gearbox casing, aligned with the rotational axis.

- Use multiple sensors for comprehensive data collection, covering different machine parts.

- Collect data during normal operating conditions for comparative analysis.

What Do Vibration Analysis Results Indicate?

Once the vibration data has been collected, it is essential to analyze the results for meaningful insights:

Key Vibration Parameters to Evaluate

- Amplitude: Indicates the severity of the vibration.

- Frequency: Helps identify specific faults; for example, certain frequencies correlate with gear wear or misalignment.

- Waveform: Visual representation of vibration over time allows you to observe patterns.

- Harmonics: Additional frequencies that can reveal issues not evident in the fundamental frequency.

Interpreting Vibration Data

Interpreting the results from gearbox vibration analysis can involve identifying:

- Fault frequencies: Specific frequencies associated with known faults.

- Trends over time: An increase in amplitude or changes in frequency patterns can indicate a worsening issue.

Comparing Vibration Levels

It is beneficial to compare current vibration levels against historical data or industry standards to assess the gearbox’s condition accurately.

When to Conduct Gearbox Vibration Analysis?

Timing for conducting gearbox vibration analysis is key to ensuring optimal performance. Here are important instances to consider:

- Initial baseline measurement: Establish a baseline immediately after installation or maintenance.

- Regular intervals: Schedule periodic analysis, ideally during routine maintenance checks.

- After maintenance: Always conduct an analysis following repairs or adjustments to check for any potential issues.

- Unexpected changes: If operations change or unusual noises/vibrations occur, a prompt analysis is necessary.

What Are the Next Steps After Vibration Analysis?

Once the gearbox vibration analysis is complete and any issues are identified, it’s critical to take appropriate action. Consider the following steps:

1. Root Cause Analysis

Investigate the underlying reasons for detected vibrations.

Understanding why the vibrations are occurring is essential for selecting the right solution.

2. Implement Corrective Actions

Depending on the findings, different actions may be necessary, such as:

- Realignment: Adjusting misaligned components.

- Balancing: Correcting any mass imbalances.

- Replacing components: If wear is significant, consider replacing faulty gears or bearings.

- Improving lubrication: Addressing lubrication issues ensures smoother operation.

3. Continuous Monitoring

Establish a continuous monitoring plan to track the effectiveness of the corrective actions and assist in ongoing gearbox vibration analysis.

Conclusion

In conclusion, effective gearbox vibration analysis is crucial for maintaining operational efficiency and extending the lifespan of machinery.

By understanding the causes of gearbox vibration, utilizing appropriate measurement techniques, and interpreting results accurately, you can implement proactive maintenance strategies that significantly reduce downtime and repair costs.

Remember to conduct regular analysis, monitor trends, and take corrective actions timely. Doing so ensures a reliable and productive machinery operation in your industrial settings.

With the insights from this guide, you should be able to take the necessary steps to manage gearbox vibrations efficiently.