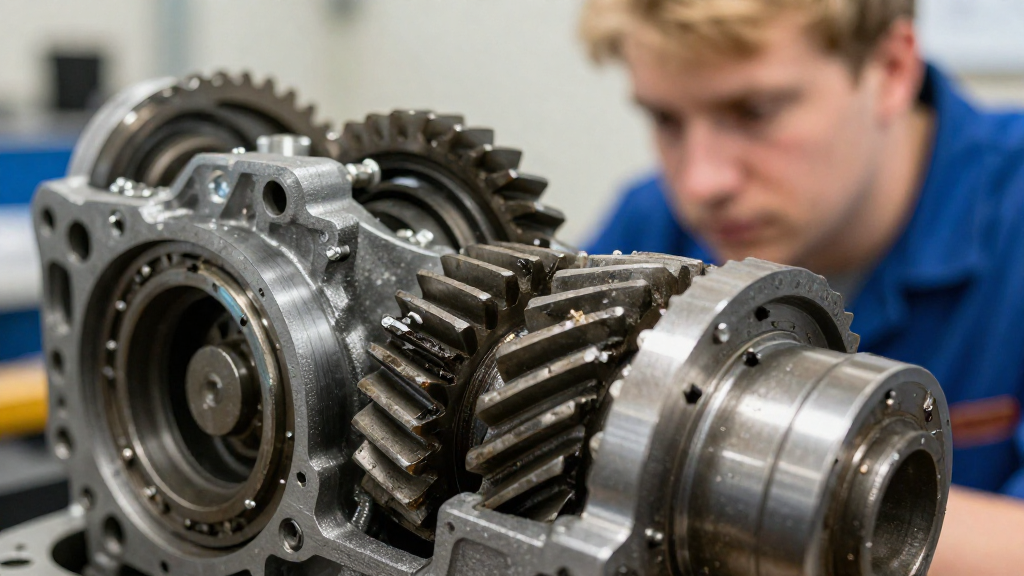

Gear tooth failure modes are critical considerations in mechanical engineering.

Understanding these failure modes can aid in the design and maintenance of more reliable gear systems.

What Are the Common Gear Tooth Failure Modes?

Gear tooth failure modes can be broadly categorized into several types, each with unique characteristics and causes.

1. Pitting

Pitting is one of the most common gear tooth failure modes.

It occurs when small surface flaws expand over time, leading to craters or pits on gear teeth.

Causes include:

- Poor lubrication

- Excessive load

- Material defects

2. Wear

Wear is another significant mode of gear tooth failure.

It results from the continual friction between gear teeth during operation.

There are different types of wear:

- Abrasive Wear: Occurs due to hard particles in the lubricant.

- Adhesive Wear: Involves the transfer of material from one tooth to another, leading to material loss over time.

3. Tooth Fracture

Tooth fracture is a catastrophic failure mode and can lead to sudden gear failure.

This mode can occur due to:

- Overloading

- Manufacturing defects

- Fatigue

4. Scuffing

Scuffing is characterized by the welding and tearing of gear tooth surfaces.

It usually occurs when gears operate with insufficient lubrication or excessive speed.

Preventive measures include:

- Maintaining proper lubrication levels

- Reducing operational speeds

5. Cryogenic Cracking

Cryogenic cracking is a less common but severe mode of failure.

It occurs when steel gears are subjected to extreme temperatures, leading to crack formation.

How Do Factors Influence Gear Tooth Failure Modes?

Several factors play a crucial role in determining the occurrence of gear tooth failure modes.

1. Materials Used

The choice of material significantly impacts gear performance.

Harder materials are often more resistant to wear but can also become brittle.

Common materials used include:

- Steel

- Aluminum

- Plastic

2. Load Conditions

The operational load conditions directly affect gear degradation.

High loads tend to exacerbate wear and can lead to fracture, while low loads may not provide sufficient engagement, leading to poor performance.

3. Lubrication Practices

Proper lubrication is vital to prevent many gear tooth failure modes.

Inadequate or inappropriate lubricants can cause wear, overheating, and pitting.

4. Gear Design

The design of the gear itself influences its susceptibility to failure.

Factors in gear design include:

- Tooth geometry

- Tooth size

- Pitch

What Measures Can Be Taken to Prevent Gear Tooth Failure Modes?

Taking preventive measures is essential for ensuring the longevity and reliability of gears.

1. Regular Inspection

Conducting regular inspections can help identify potential issues early.

Key areas to assess include:

- Surface wear patterns

- Lubrication levels

- Tooth engagement

2. Optimal Lubrication

Ensure that gears are properly lubricated.

Selecting the right lubricant type based on operational conditions can reduce wear and prevent pitting.

3. Load Management

Managing operational loads effectively can prevent excessive stress on gear teeth.

Strategies include:

- Monitoring load conditions

- Applying load limits within manufacturer specifications

4. Material Selection

Choosing the right material for specific applications is crucial.

Consider using materials that offer better wear resistance and toughness.

How Can Technology Help with Gear Tooth Failure Modes?

Recent advancements in technology have provided new tools for understanding and preventing gear tooth failure modes.

1. Predictive Maintenance

Predictive maintenance uses technology to analyze data and predict potential gear failures.

By monitoring factors such as vibration and temperature, it can help identify early signs of failure.

2. Finite Element Analysis (FEA)

Finite Element Analysis (FEA) allows engineers to simulate stresses and deformation in gear systems before they are manufactured.

This technology can identify weak points and improve gear design, minimizing failure risks.

3. Condition Monitoring Systems

Implementing condition monitoring systems can help in the continuous assessment of gear systems.

These systems can track wear over time and provide alerts for maintenance needs.

Conclusion: Understanding Gear Tooth Failure Modes

In conclusion, gear tooth failure modes present various challenges, but understanding them can lead to more reliable gear systems.

From pitting to tooth fracture, being aware of these failure modes and their causes enables better design and maintenance strategies.

Implementing preventive measures, utilizing technology, and ensuring proper material selection contribute to minimizing these failures.

By taking these proactive steps, engineers and technicians can enhance the longevity and reliability of gear systems, ensuring they perform effectively under various conditions.

Investing time and resources into understanding gear tooth failure modes is essential for optimal performance and safety in any mechanical application.