How Does a Bicycle Gear Mechanism Work?

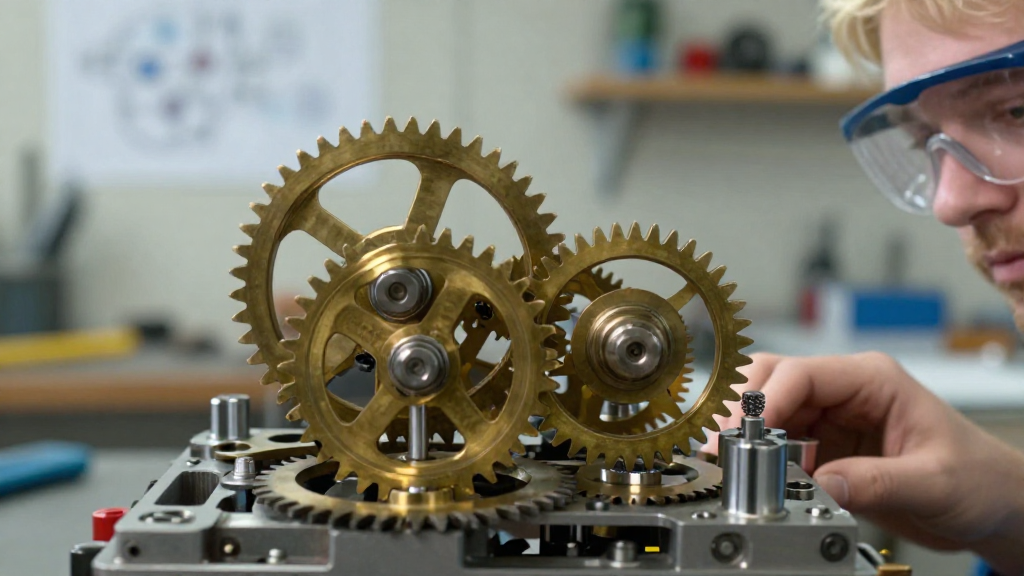

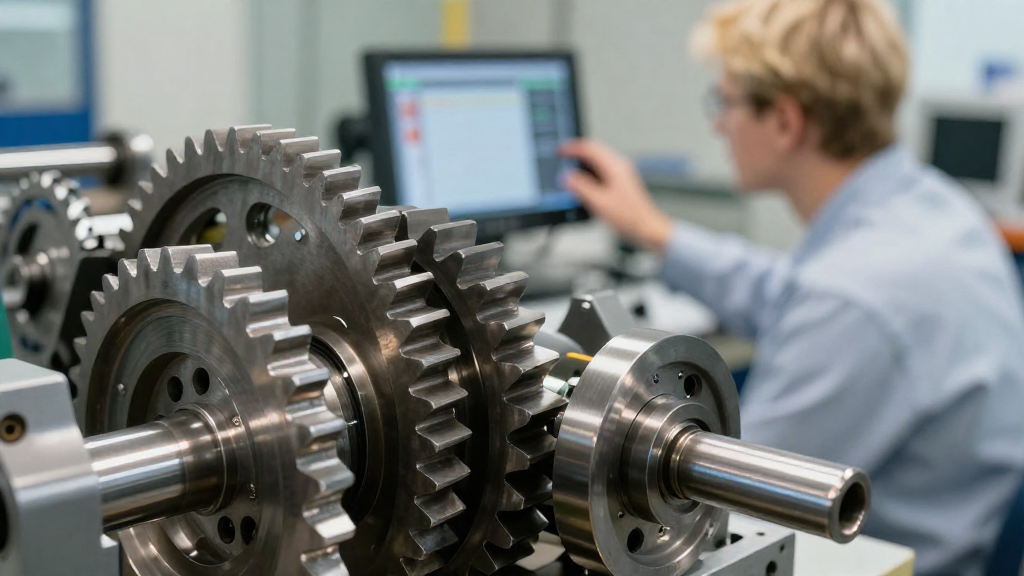

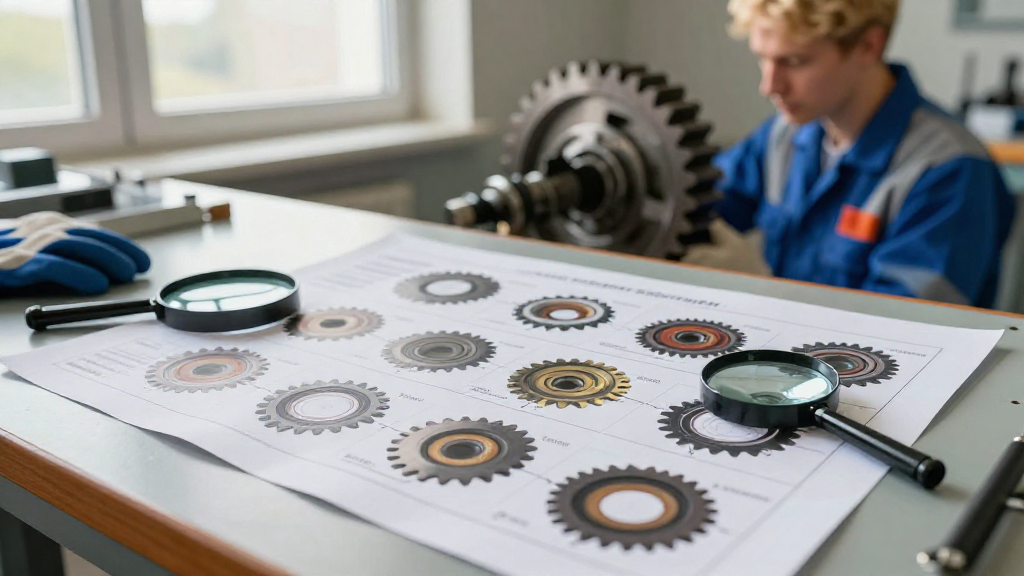

Understanding how a bicycle gear mechanism operates is essential for both casual riders and cycling enthusiasts. This article will delve into the various components and workings of a bicycle gear mechanism, making it easier for you to appreciate its intricacies. What Are the Key Components of a Bicycle Gear Mechanism? A bicycle gear mechanism consists … Read more